When crafting whiskeys like those from The Craft Irish Whiskey Co., using smaller barrels has the potential to add an unrivalled intensity of flavour. But it takes an expert palate to do this without overpowering other flavours. Find out how in our guide.

When it comes to ingredients, whiskey is a fairly simple and straightforward liquid. You can’t use anything other than grain, water, and yeast to produce it. But as soon as it hits the barrel —where it will develop the majority of its flavour— things start to get complicated. There are so many variables at play at this point, from the type of wood used (American Oak, European Oak, ex-bourbon cask, ex-port cask, ex-sherry cask are all popular options), to whiskey storage – the prevailing climate of the area in which it ages, and even where it sits in the warehouse; all of these play a major role in shaping the final product inside. Whether you’re talking about Irish single malt or the Scotch industry, it’s the same story; you can’t rely on any flavour additives to shape the spirit. It’s all down to those three primary ingredients.

What are the standard whiskey barrels?

Here we’re going to focus on one of the most controversial of these variables in whiskey production: barrel size. Specifically, we’re going to let you know why we incorporate smaller barrels into our whiskey maturation process, and how it helps nurture the complexities in our award-winning whiskey. The vast majority of bourbon, rye, Scotch and Irish Whiskey all age in casks of around 200 litres in size, though port pipes and sherry butts are much larger—ranging up to 500 litres for the latter.

These larger vessels are standard in whiskey making for a reason. They offer an ideal ratio of surface area to volume for a slowly maturing spirit. That is, the amount of whiskey in contact with the inside of the barrel—the precise point where flavour extraction from the wood occurs—is at a level that favours patient ageing. Because with certain types of distillate, particularly those that are high in corn, it’s not just about what the wood is putting in, it’s about what the wood is taking out—namely some of those fusel alcohols that can cause a burning sensation on the palate. After all, there’s a reason why we age the stuff in whiskey barrels. It invariably tastes better than new make spirit!

The Scotch industry knows this to be the case, but they aren’t afforded the same freedoms that Irish whiskey is when it comes to barrel ageing. You see, in Scotland, a whiskey distillery is required by law to use oak barrels. In the Emerald Isle, however, whiskey makers are able to use casks cut from all sorts of wood including chestnut, cherry, acacia. Anything that’s watertight is good to go into the barrelhouse. This is why, according to many experts, the rapidly growing Irish whiskey industry is poised to overtake the Scotch market at some point over the next couple of decades. But that is a topic for another day. Let’s get back barrel ageing and reiterate the point that although Scotch and Irish whiskey most both enjoy a minimum ageing of three years, they quite often are spending many years more than that in the cask.

Finishing Barrels

After primary maturation has concluded, many of the most exciting whiskeys on the planet today are exposed to a secondary process known as ‘finishing.’ And it’s in this stage that the introduction of smaller whiskey barrels can be critical to success. In the Scotch industry, many master blenders rely on ‘quarter casks’ (about a quarter the size of a 500 litre sherry butt) to deliver more interaction with wood than a standard whisky cask, but still allow for prolonged time in the warehouse.

When you go smaller than that with your whiskey casks, you can supercharge flavour development during the finishing process, but you also run the risk of infusing too much wood flavour into the liquid. Whiskey makers can avoid the latter outcome through an intimate knowledge of how any particular ageing vessel works and through meticulous monitoring throughout the ageing—we’re talking barrel sampling up to several times a day in the warehouse. And that’s how The Craft Irish Whiskey Co. is able to introduce Octaves (50 litre casks providing robust interaction between wood and spirit) as well as Blood-tubs (the smallest and most tricky cask of them all) with expert effect.

Award-winning whiskeys and whiskey companies don’t just come about by chance. It’s a function of intense knowledge and fastidious monitoring–especially when you’re working with the aforementioned blood-tubs. The relative proportion of surface area exposed to the wood in these smaller vessels is way greater than in a sherry butt or even a standard whiskey cask. And what that means is, you can run the risk of getting too much wood notes into the spirit if there isn’t an incredibly skilled maturation specialist tending to the barrels.

The Skill of a Chef

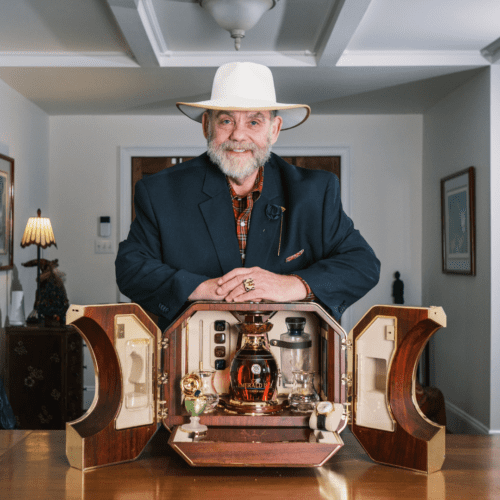

Think of an intense spice such as saffron, turmeric, saffron. These flavour additives can easily ruin a dish when applied haphazardly. In the hands of a world class chef, however, they inform and inspire Michelin-calibre cuisine. It’s no coincidence that The Craft Irish Whiskey Co. founder and Master Blender Jay Bradley was a world class chef before entering the whiskey business. He knows how to work with flavour on a precise level. It’s not an easy process, and it comes at a steep price (beyond that of just a tipsy taster). Yet it is unquestionably worth the investment when you taste the end result.

In just a few short years Jay Bradley has built The Craft Irish Whiskey Co. into one of the leading brands of ultra premium spirit on the planet. Although it’s been just 4 years since he started the actual business, he’s actually spent a lifetime honing his skillset: flavour development. The recipe seems simple and straightforward…You start with a great new make spirit, you allocate time and effort to proper whiskey storage, and that brilliant nectar pours out years later.

But in reality it’s so much more complicated than that. For Bradley it’s an endeavour that requires him being on the clock 24 hours a day, 7 days a week; checking in on his stock and constantly analysing organoleptically to see how the evolution is progressing throughout the whiskey maturation process. Remember that ageing and maturation are two separate concepts. Everything gets older with the steady passage of time, but not everything matures. The difference, when it comes to quality whiskey, is largely owed to the hand of the maker. Bradley, for his part, refuses to bottle any liquid that he doesn’t personally rate as a 9 out of 10, minimum. He’s not the only one reserving such high marks for the product, either.

An award-winning result

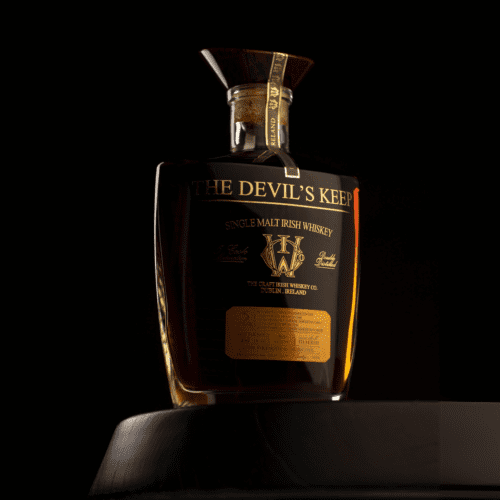

The proof is in the judging. At the World Whiskies Awards in March 2022, The Craft Irish Whiskey Co.’s inaugural release, The Devil’s Keep, was named the world’s Best Irish Single Malt. It’s incredibly rare recognition for a newcomer in the business and testament to the talented maturation team that’s crafting those magical liquids. By paying close attention to the finer details, and investing time, energy and passion into reimagining the process of whiskey maturation, every ultra-rare single malt crafted by the company has been awarded the highest accolades by independent experts and judges. This is just the beginning though. As is so often the case with whiskey, we’re getting better with age.